Introduction

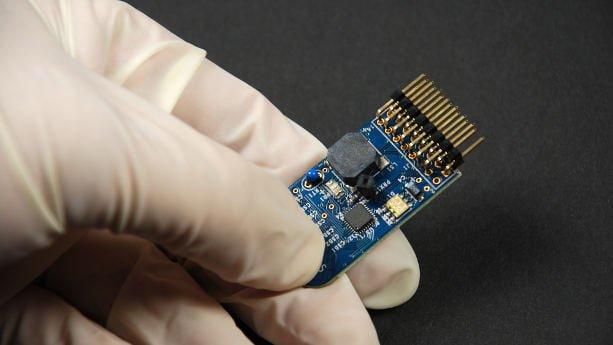

In the early 21st century, the proliferation of electronic waste and the use of hazardous chemicals, like radium luminescence and lead-tin alloys, posed significant risks to human health and the environment. These risks were largely unrecognized until hundreds of thousands of people developed serious health problems, including lung cancer, mesothelioma, and asbestosis. To address this issue, the European Union introduced the Restriction of Hazardous Substance (RoHS) directive in February 2003.

The RoHS directive came into effect on July 1, 2006, and was mandated to be enforced in every member state. RoHS aims to restrict the use of specific hazardous substances in electrical and electronic equipment, with the primary goal of reducing environmental impact and health risks associated with electronics.

What is RoHS Certification?

RoHS, which stands for Restriction of Hazardous Substances, is also known as Directive 2002/95/EC. It outlines restrictions on the use of certain hazardous substances in electrical and electronic equipment. RoHS falls under the Waste Electrical and Electronic Equipment (WEEE) category.

As electronic product demand in India continues to surge, there is an increasing threat to the environment and human health. Rapid technological advancements also lead to the rapid disposal of electronic devices, contributing to a significant rise in electronic waste. To address these concerns, the Ministry of Environment and Forest (MoEF) and the Government of India implemented the Restriction of Hazardous Substance, known as Electronic Waste in India.

Depending on the size and type of electronic products produced or imported in India, companies may have responsibilities under WEEE or RoHS regulations.

Substances Prohibited Under RoHS Certification

RoHS restricts the use of several hazardous substances, including:

- Polybrominated Diphenyl Ethers (PBDE)

- Polybrominated Biphenyls (PBB)

- Hexavalent Chromium (CrVI)

- Cadmium (Cd)

- Mercury (Hg)

- Lead (Pb)

Exempted Products Under RoHS Certification

Certain products are exempt from RoHS certification, including:

- Military and National Defense products

- Products not primarily reliant on electricity as their energy source

- Products whose primary function does not necessitate electricity

- Sub-assemblies or components of exempted product categories

- Products supporting micro, small, and medium-sized manufacturing and service firms

- Batteries

- Radioactive waste

Process of RoHS Certification

The RoHS certification process involves several steps:

Documentation Review: Evaluate and confirm the status of relevant documents, such as bills of materials, material declarations, assembly drawings, conformance certifications, and test results. Create a compliance file.

Verification: Conduct on-site or XRF testing and/or lab phthalate solvent extraction testing to confirm compliance with the RoHS thresholds for the 10 prohibited substances.

End Product Analysis: Inspect all relevant manufacturing processes for RoHS compliance, including a review of goods, control of prohibited substances, and a full factory inspection.

Grant of License: Upon successful completion of the audit and compliance review, a RoHS certificate (Certificate of Conformity or Declaration of Conformity) is issued.

Technical File Requirements

The technical file for RoHS certification should include:

- Product description, design, and structure information

- Material, part, and subassembly risk assessments

- Material, part, and subassembly conformity information

- Records and documentation from the manufacturing process

- Standards, specifications, and conformance procedures

How to Get RoHS Certification in India with Electronics India

The RoHS certification process is crucial for ensuring the safety of electronic products and preventing the use of hazardous substances like lead and beryllium oxide. Electronics India is here to guide you through the steps of obtaining RoHS certification in India:

Identify Risks: Begin by identifying potential risks in your production processes and supply chain.

Operational Review: Examine every stage of your operations to identify areas where RoHS compliance may be at risk.

Quality Control: Implement stringent quality control measures to eliminate causes of non-compliance and reduce risks.

Document Review: Ensure that all necessary documents, including bills of materials, technical files, assembly drawings, material declarations, test reports, and compliance certificates, are in order.

Compliance Certification: After a successful audit and compliance review, you will receive a RoHS Certification, which acts as a Certificate of Conformity.

In summary, RoHS certification is crucial for the safety of electronic products and the environment. Electronics India is your trusted partner in ensuring that your electronic equipment complies with RoHS regulations and does not contain any of the 10 prohibited substances. We are dedicated to helping you navigate the complexities of RoHS certification in India.